You probably know that gas turbines are playing crucial role in a power generation for more than a century, especially because the world is in growing demand for power and energy. Back in the day, gas turbine designs were cornerstone of power production, and they remain essential aspects of driving electricity generation, transportation systems and industrial applications.

The best way to learn more about this particular topic is by entering here for more info. In this particular article, we will explore the way they work, essential components, different options you can find on the market, heating and cooling mechanisms and other factors that will help you throughout the process.

Key Components

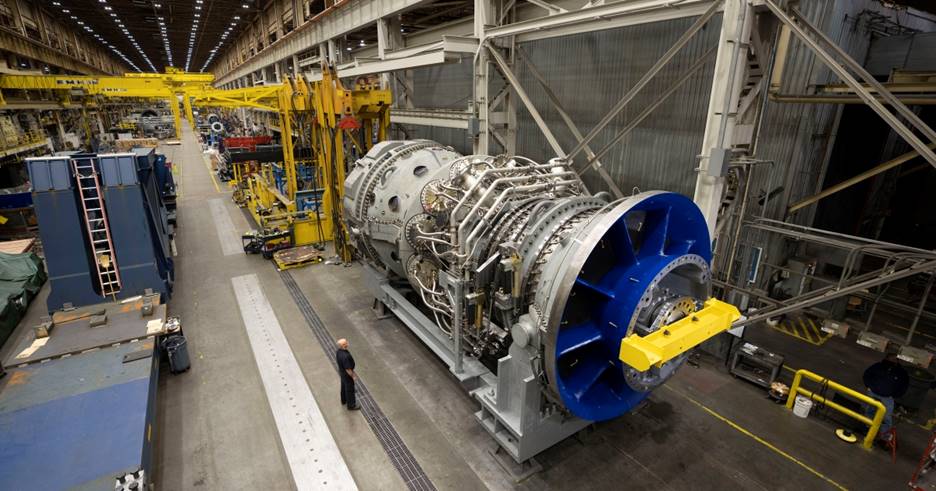

Although they seem complex while operating, you should know that gas turbines tend to rely on three components that are crucial: the compressor, the combustion system and the turbine. Each aspect comes with a crucial role in ensuring the efficient energy conversion.

You should know that compressor could draw in air and pressurize it before sending it into the combustion chamber at speeds reaching hundreds of miles per hour. Inside the combustion system, fuel injectors can easily spray natural gas within the chamber, which will ignite it at exceptional temperatures that can reach up to two thousand degrees.

Afterward, the high-temperature gas expands and enters the turbine, where it spins the blades inside. The rotational force drives the generator, which produces electricity. You should remember that a motion is pulling more air into the compressor, which creates continuous energy cycle.

Different Types of Gas Turbines

We can differentiate different types of gas turbines that are classified based on the application and why do you need it in the first place. Therefore, we can differentiate three major classifications, specifically vertical flow, centrifugal flow and rotational-axial flow.

Check out this website: https://www.eia.gov/energyexplained/electricity/electricity-in-the-us.php to learn more about electricity generation in the US.

Gas Turbines Based on Compression

- Centrifugal Flow – The compression process entails the acceleration of incoming air in an outward direction compared with the longitude of the turbine.

- Axial Flow – As the name suggests, this particular engine features series of static and rotational airfoils that can achieve air compression, which results in parallel movements along the longitudinal motion options.

- Centrifugal-Axial Flow – The centrifugal-axial flow arrangement takes advantage of hybrid design between axial and centrifugal compressor, which will allow you a chance to achieve the required compression level.

Turbo Jet

You should know that a turbojet engine, similarly as other options you could find on the market feature four specific sections including the compressor, turbine, combustion and exhaust. The compressor is facilitating the rapid flow of input air towards the chamber.

Later you will propel the turbine by expanding the air, while you can mechanically link it to a compressor through a shaft, which will ensure the overall functioning of an engine. The high-end exhaust gasses tend to emit from the engine, which generates strong propulsion.

This is a high-end representation of an air compression, which will offer you an exceptional functionality, while reducing exhaust gases to a minimum.

Air Compressor

You probably understand that an air compressor is a mechanical device specifically used to convert power from a primary energy source, which can be either internal combustion engine or electric motor.

It is specifically located in the intermediary space that connects the combustion chamber and turbine. The air compressor and turbine are within the shared shaft. Gas turbines are taking advantage of the presence of a starting motor, due to absence of self-starting capabilities.

The essential function of an air compressor is to take air and compress it afterward, which will increase its pressure altogether. Taking advantage of axial design compressor is favorable solution for ensuring the overall pressure and preventing the energy inefficiency.

Aero-Derivative Gas Turbine

We are talking about the type of gas turbine that takes advantage from jet engines. It is specifically engineered to be lightweight and compact, making it perfect for marine and mobile settings. You should remember that aero-derivative gas turbines are widely recognized and popular in airplane propulsion, mobile electric power generator and marine propulsion.

Combustion Chamber

We are talking about a crucial component within the internal combustion engines, which are taking advantage of gas turbine. That way, you can combine air and fuel to ensure the combustion and flow of power.

When you take advantage of this particular aspect, the process takes advantage of fuel and compressed air, meaning you will generate air-fuel amalgam that leads to combustion altogether. Before checking out turbine rotor repair, you should know that combustion byproducts would later go into the gas turbine.

The presence of elevated air pressure is essential for optimal burning of fuel, which is vital to remember.

Micro-Turbine

You should remember that a micro-turbine is a gas turbine, which is specifically created for the purpose of decentralized power generation. It can easily cater to various scenarios as a form of contingency plan in rural areas as the power source. It is also utilized through various settings including industrial, commercial and residential.